15000+

Professionals Trained

50+

Countries Students

99%

Satisfaction Rate

50+

Placement Partners

Professionals Trained

Countries Students

Satisfaction Rate

Placement Partners

Tailored guidance based on your background, goals & industry trends

Stand out with an expertly reviewed resume and Piping project portfolio

Learn how to negotiate your worth and explore freelancing in EPC industry

Craft a professional LinkedIn profile that gets recruiter attention globally

Get real interview experience and feedback from industry professionals

Get exclusive access to our global hiring network across India, the Gulf, and Tier-1 countries — connecting you with high-impact roles and the best career opportunities

A practical, career-focused approach guided by experts— designed to help you master skills, build real world projects, and get hired

Attend interactive sessions led by professionals working in leading EPC firms. Learn directly from real project experience, ask questions, and stay aligned with industry standards.

Get dedicated guidance from seasoned experts who’ll help you navigate complex software tools and career decisions.

Work on capstone projects modeled after real Piping workflows. Build a portfolio that gets noticed by recruiters

Receive detailed expert feedback on your assignments to improve accuracy, clarity, and professional readiness

Receive detailed expert feedback on your assignments to improve accuracy, clarity, and professional readiness

Have a single point of contact for non-academic support, from scheduling to technical help, so nothing blocks your learning

Module 1: Introduction to Piping Engineering & Industry Overview

Duration: 6 Hours

Duration: 6 Hours

Duration: 3 Hours

Duration: 6 Hours

Duration: 6 Hours

Duration: 3 Hours

Duration: 6 Hours

Topics Covered:

Understanding the Interface and Tool Palettes

Navigating the Project Manager

Creating P&IDs Using Standard Libraries

Adding Equipment, Lines, and Annotations

Student Activities:

Create a simple P&ID diagram from a given process

Use standard symbols and annotations

Mini Project:

Prepare a complete P&ID for a basic pump-to-tank system

Topics Covered:

Component Tagging and Data Linking

Assigning Line Numbers and Equipment IDs

Generating Component Lists and Line Lists

Data Consistency and Audit Checks

Student Activities:

Edit and update tag properties for a given diagram

Perform error checks using Data Manager

Mini Project:

Generate an intelligent line list and equipment list from your own P&ID

Topics Covered:

Setting up a Plant 3D Project

Understanding the Folder Structure and Spec Files

Importing P&ID Data into 3D Environment

Student Activities:

Set up a sample Plant 3D project

Link existing P&ID data to 3D workspace

Mini Project:

Configure a project and import your P&ID model

Topics Covered:

Creating Custom Equipment Using Equipment Builder

Placing Standard Pumps, Vessels, Tanks, and Exchangers

Nozzle Orientation and Alignment

Student Activities:

Model a vessel and pump in 3D

Adjust nozzle direction and elevations

Mini Project:

Build an equipment layout for a sample process plant zone

Topics Covered:

Routing Pipelines Using Spec-Driven Modeling

Adding Elbows, Reducers, Valves, Flanges

Using Pipe Routing Preferences and Elevation Settings

Student Activities:

Route piping between two equipment in 3D

Insert valves and fittings with correct orientation

Mini Project:

Model a complete line from pump to tank using correct spec

Topics Covered:

Adding Pipe Supports and Hangers

Creating Isometric Drawings and Customizing Annotations

Generating Bill of Materials (BOM) and Spool Drawings

Student Activities:

Add supports to existing 3D lines

Generate isometrics for individual lines

Mini Project:

Generate isometric and BOM for a complete line system

Topics Covered:

Creating Orthographic Views: Plan, Elevation, Section

Dimensioning, Annotation, and Title Block Editing

Plotting and Sheet Setup for Deliverables

Student Activities:

Extract ortho views from your plant model

Apply dimensioning and annotation settings

Mini Project:

Submit a plot-ready ortho sheet for review

Project Scope:

Model a complete pump circulation loop including pump, suction drum, delivery tank, valves, reducers, flanges, and supports

Develop intelligent P&ID and link it to Plant 3D

Route all piping lines with correct specs and elevations

Generate isometrics, orthographic drawings, BOM, and project data reports

Student Activities:

Peer review and checklist-based QA of model and drawings

Final Submission:

Linked P&ID and Plant 3D model

Isometrics and BOM

Ortho drawings (plan and section)

Design basis note

Topics Covered:

Overview of SP3D interface and workspace

Understanding database-driven modeling

SP3D project structure and environment setup

Work breakdown, permissions, and admin roles

Student Activities:

Explore interface and component hierarchy

Set up a sample SP3D workspace

Mini Project:

Create a new SP3D project and configure the grid and workspace

Topics Covered:

Placing equipment: pumps, vessels, exchangers

Modifying dimensions, orientation, and nozzles

Basic steel structure modeling for platforms and racks

Inserting reference planes and setting elevations

Student Activities:

Model a pump and vertical vessel with nozzles

Create a steel support frame using structural tools

Mini Project:

Complete a model of a pump skid with platform and vessel

Topics Covered:

Creating pipelines using spec-driven routing

Inserting elbows, tees, reducers, and custom fittings

Using pipe hierarchy: systems, runs, and branches

Assigning specs and insulation layers

Student Activities:

Route a pipe between pump and vessel

Apply correct specs and elevation offsets

Mini Project:

Model a full line system for a tank feed loop using SP3D specs

Topics Covered:

Using pipe support module

Inserting supports, spring hangers, and baseplates

Modifying support types based on line service

Student Activities:

Insert supports for horizontal and vertical lines

Configure a custom support assembly

Mini Project:

Apply appropriate supports for a pressure line with elevation changes

Topics Covered:

Managing nozzles and connectivity

Nozzle alignment with pipe routes

Equipment-to-pipe integration

Student Activities:

Align nozzle direction for pump suction/discharge

Fix a disconnected line using the routing tool

Mini Project:

Model a connected loop between pump, vessel, and pipe rack

Topics Covered:

Running clash detection within SP3D

Managing interferences using filters

Clash resolution reporting and coordination

Student Activities:

Run clash check for a modeled plant area

Generate and interpret clash report

Mini Project:

Resolve interferences in a congested piping area and submit clash-free version

Topics Covered:

Generating isometrics automatically

Customizing drawing templates and annotations

Creating ortho drawings: plan, elevation, and sections

Exporting and publishing deliverables

Student Activities:

Generate isometric drawings for a selected line

Create orthographic view with annotations

Mini Project:

Submit isometric and ortho drawing set for a modeled system

Project Scope:

Model a full compressor unit including:

Centrifugal compressor

Suction drum and aftercooler

Interconnected piping with routing via a pipe rack

Supports, nozzles, valves, and connectivity

Include line specs, drawing outputs, and clash-free model

Student Activities:

Peer review and validation checklist

Final Submission:

SP3D model

Isometrics and ortho sheets

Bill of Materials (BOM)

Clash report

Topics Covered:

What is pipe stress and why it matters

Types of loads: sustained, thermal, occasional

Failure modes: fatigue, creep, buckling

Code overview: ASME B31.1, B31.3 stress criteria

Student Activities:

Identify stress zones in a sample piping layout

Map loads on a sample pipe routing

Mini Project:

Document stress concerns in a high-temp pump line scenario

Topics Covered:

Interface walkthrough and input setup

Creating a piping model: nodes, elements, restraints

Input of material, temperature, pressure, and pipe data

CAESAR file formats and navigation

Student Activities:

Build a basic L-shaped pipe model

Input operating and design conditions

Mini Project:

Model a horizontal line with reducers, bends, and supports

Topics Covered:

Understanding primary and secondary stresses

Load cases: W+P, W+P+T, occasional (wind/seismic)

Sustained stress and expansion stress checks

Displacement and stress result interpretation

Student Activities:

Analyze a modeled line under W+P+T

Compare output with ASME allowable limits

Mini Project:

Perform complete static analysis of a process line and summarize results

Topics Covered:

Why expansion loops are needed

Expansion stress and displacement limits

Loop sizing formulas and flexibility checks

Support configuration: anchor, guide, spring hanger

Student Activities:

Add an expansion loop to an existing model

Calculate loop dimensions manually

Mini Project:

Modify a rigid layout into a flexible one and compare results

Topics Covered:

Types of supports: fixed, sliding, spring, variable

Modeling restraints and stiffness

Guide spacing and anchor loads

Student Activities:

Apply spring hangers in a vertical riser

Evaluate support reactions and check overstressed zones

Mini Project:

Add complete support logic to a stress-critical system

Topics Covered:

Modeling wind and seismic loads

Using uniform loads and response spectrum

Hydrotest case setup

Student Activities:

Apply wind load to a pipe rack system

Analyze effects of earthquake loading in a riser

Mini Project:

Analyze a vertical column line with wind and seismic loads

Topics Covered:

Reviewing code compliance reports

Generating support load reports and displacement summaries

Preparing deliverables: stress isometrics, load tables

Student Activities:

Interpret CAESAR output reports

Create a compliance checklist based on project specs

Mini Project:

Submit documentation for a completed stress model with findings and design notes

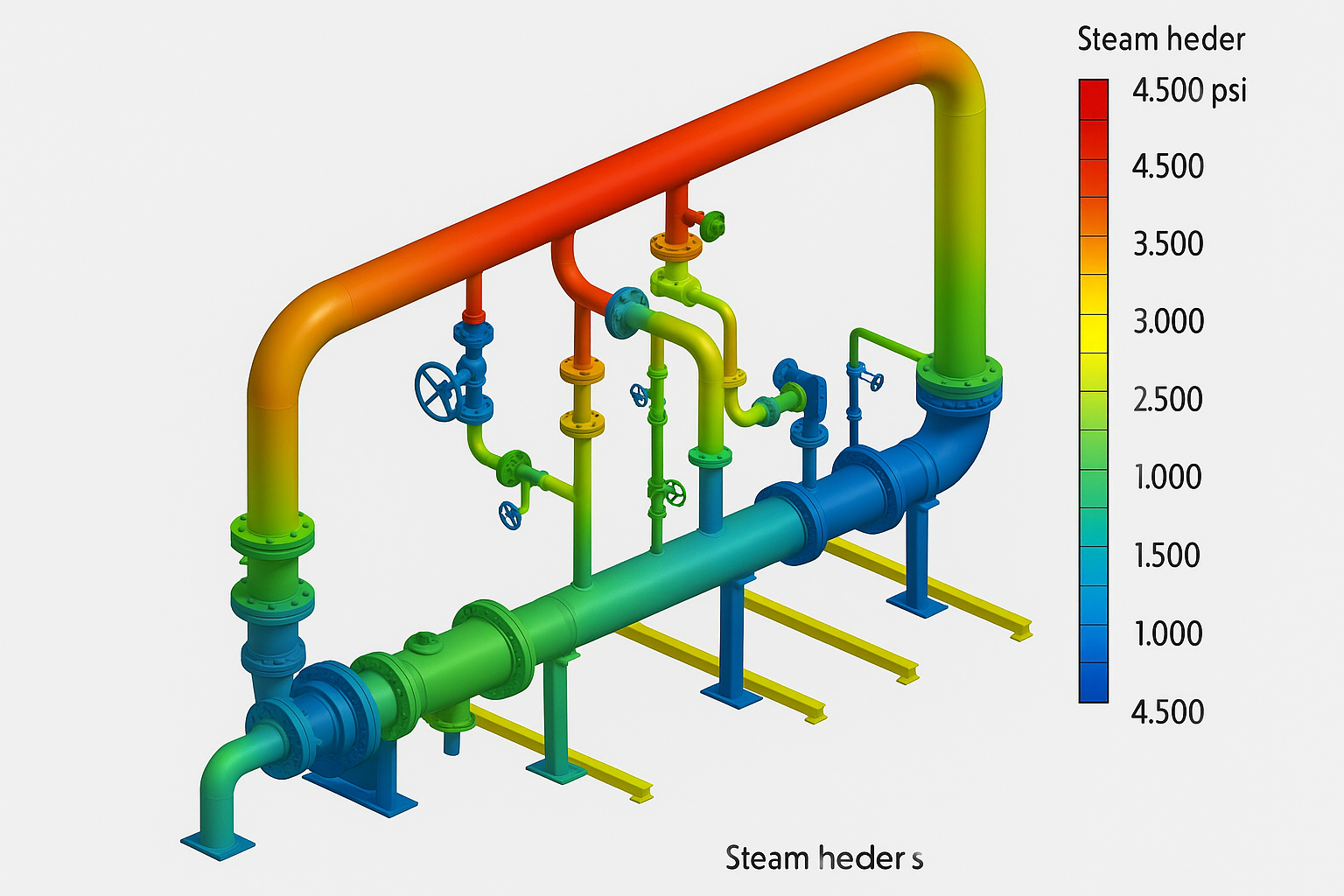

Project Scope:

Model a steam distribution line with branches, valves, and elevation changes

Apply temperature, pressure, and occasional loads

Add expansion loops, proper supports, and restraints

Ensure stress compliance with ASME code

Student Activities:

Peer-review another student’s model

QA checklist verification of model assumptions

Final Submission:

CAESAR II model file

Load case setup and results

Stress isometric with support locations

Final report with conclusions and recommendations

These projects will push your design skills, enhance your technical expertise, and prepare you to work on real-world piping systems used across global EPC and process industries.

Your Gateway to International Opportunities.

Gain Practical Skills, Expert Guidance, and Career Opportunities Tailored for Non-Tech Professionals

Detailed Piping programs for working professionals and students

Personalized counseling to navigate career transitions effectively

Dedicated support for job search and industry connections

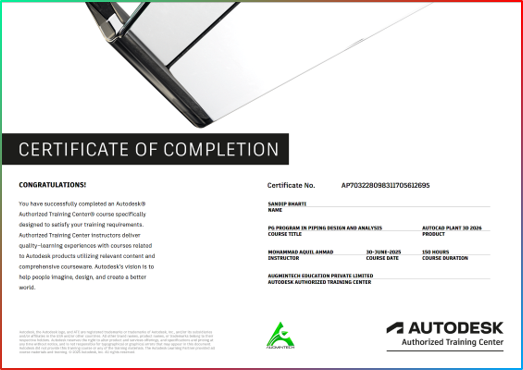

Recognized by AutoDesk, ISO, MSME, IAF and IAS

Upgrade Your BIM Career : Affordable Course Pricing Options

Upgrade Your BIM Career : Affordable Course Pricing Options

Yes, our PG Program covers everything from basic to advanced level with complete projects.

Mechanical, Civil, or Electrical Engineers, , Graduates and Postgraduates from Diverse Fields, Professionals from Non-Tech Backgrounds

Each live session lasts for 2-3 hours, and total live class duration is 200 hours over 6 months.

No specific prerequisites are required, and all necessary software will be provided during the program

Links will be shared in a dedicated WhatsApp group 2-3 hours before each session.

Upon successful completion, you'll be awarded a certification accredited by ISO, MSME, IAF, and IAS.

Yes, recordings are available in Website for 1000 days.

Internship opportunities are available across industries and locations, providing flexibility based on your preferences and qualifications.

Additional materials are downloadable through Google Drive.

After completing the program, you'll be qualified for roles such as Piping designer industries across India, UAE, KSA, USA, Canada, or Australia

Ready to supercharge your career and unlock new opportunities? Download our comprehensive course brochure now and discover the path to success!

10000+ Successful Career Transitions. Contact Us Today and Next Could be You

23/506, 1st Floor, Laxmi Complex, Sakchi, Jamshedpur, India-831001

support@augmintech.com

+919661473085

Want to receive push notifications for all major on-site activities?

By submitting, you agree to Augmintech’s Terms and Privacy policy

By submitting, you agree to Augmintech’s Terms and Privacy policy