HVAC Chilled Water Systems

Chilled Water System Basics

Chilled water systems in residential HVAC systems are extremely rare. A typical chiller uses the process of refrigeration to chill water in a chiller barrel. This water is pumped through chilled water piping throughout the building where it will pass through a coil. Air is passed over this coil and the heat exchange process takes place. The heat in the air is absorbed into the coils and then into the water. The water is pumped back to the chiller to have the heat removed. It then makes the trip back through the building and the coils all over again. Chilled water systems circulate cold water of between 40º F to 45º F through the air to water air handlers.

As the air is cooled and passed through the finned coil, it gives up heat to the water. Most chilled water systems are designed so that, at the maximum air-conditioning load, the water leaving the coil has been heated 10º F. Chilled water systems – In a chilled-water system, the entire air conditioner is installed on the roof or behind the building. It cools water to between 40- and 45-degrees Fahrenheit (4.4 and 7.2 degrees Celsius). The chilled water is then piped throughout the building and connected to air handlers. This can be a versatile system where the water pipes work like the evaporator coils in a standard air conditioner. If it’s well-insulated, there’s no practical distance limitation to the length of a chilled-water pipe.

Advantages of chilled water systems.

Also, using a chilled water system provides better energy efficiency than smaller, individual systems. That is another important aspect. While chillers might be a more expensive initial investment, they allow have a more efficient system and save money on energy consumption. Therefore, they allow a good return on the investment in a relatively quick timeframe.

Chilled water systems also produce less noise than air ducts, which improves comfort for occupants. This is a significant advantage in office buildings, where constant noise and vibration from an air duct system can cause distraction and lower productivity.

For a specified cooling load, a chilled water system normally provides a higher efficiency than an air conditioning system with only air ducts. This can be a significant advantage in commercial buildings, where the extra efficiency yields thousands of dollars in monthly savings.

Disadvantages of chilled water systems.

One of the common problems in chilled water systems is low delta T syndrome. The problem is low chilled water return temperature that can be caused by multiple different issues such as dirty filters/coils, imbalance water flow and oversized air handling units.

These complex machines require a lot of maintenance to keep them in good working order. If proper steps aren’t taken, the chiller can corrode, clog, lose efficiency, or experience several other issues. For example, if proper water treatment isn’t maintained or if open cooling towers aren’t cleaned, sediment or particulates can be introduced to the system, causing clogged pipes and poor heat transfer. An air-cooled chiller’s condenser can be blocked by debris or become caked in dirt, which also lowers efficiency.

Disadvantages of air-cooled engines: a large amount of power is used to drive the cooling fan. -Engines give low power output. -Cooling fins under certain conditions may vibrate and amplify the noise level. -Cooling is not uniform. -Engines are subjected to high working temperatures.

Chilled water systems for commercial buildings.

Introduction

In the realm of commercial buildings, efficient cooling systems are essential for maintaining comfortable indoor environments. Chilled water systems have emerged as a popular choice due to their effectiveness, reliability, and energy efficiency. In this blog, we will delve into the world of chilled water systems, exploring their components, mathematical principles, and practical applications.

Components of Chilled Water Systems

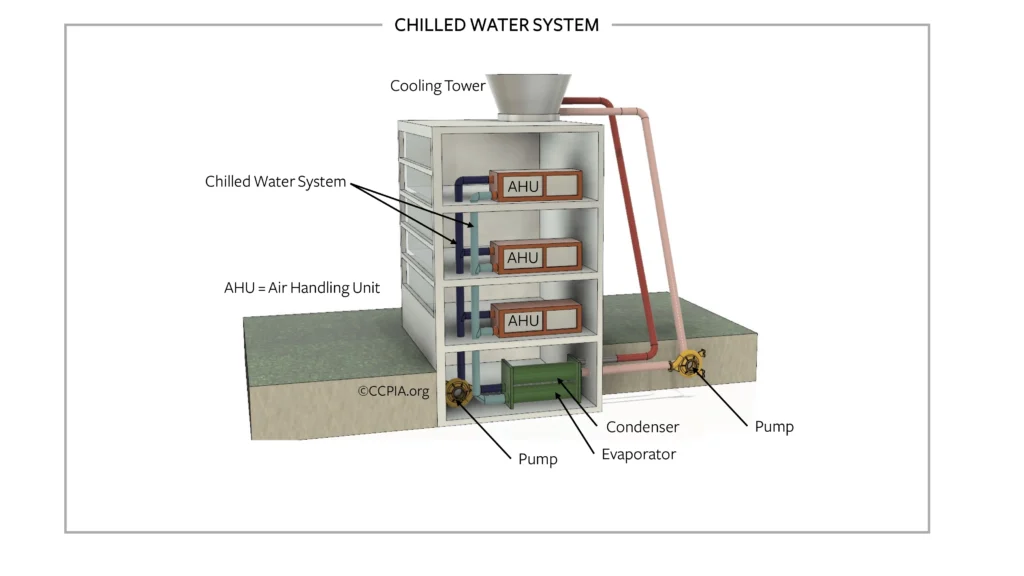

Chilled water systems consist of several key components that work together to provide effective cooling. These include chillers, cooling towers, pumps, air handling units, and chilled water distribution piping.

- Chillers: The heart of a chilled water system, chillers extract heat from the building’s air or water and transfer it to the chilled water loop. Common types of chillers include centrifugal, screw, and scroll compressors. The choice of chiller depends on the specific cooling requirements and energy efficiency goals of the building.

- Cooling Towers: Cooling towers dissipate heat from the chiller’s condenser water by using evaporation. They play a crucial role in rejecting heat and maintaining optimal chiller performance. The cooling tower cools the warm condenser water, which is then circulated back to the chiller for the cooling process to repeat.

- Pumps: Pumps are responsible for circulating chilled water through the system. They maintain the flow rate required for proper cooling and ensure efficient heat transfer. Piping systems distribute chilled water from the chiller to various air handling units or terminal units throughout the building.

- Air Handling Units (AHUs): AHUs distribute cooled air throughout the building. They consist of fans, filters, cooling coils, and dampers. The chilled water circulates through the cooling coils, absorbing heat from the air and providing cool air for indoor comfort.

Mathematical Principles and Practical Applications

Chilled water systems involve various mathematical principles and calculations to ensure optimal performance and energy efficiency.

Cooling Load Calculation: Accurate cooling load calculations are essential to determine the size and capacity of the chiller required for a commercial building. Factors such as building size, occupancy, solar heat gain, and internal heat loads are taken into account to determine the cooling load.

- Energy Efficiency Ratio (EER): The EER is a mathematical indicator of a chiller’s efficiency. It represents the cooling capacity of the chiller divided by its power consumption. Higher EER values indicate more energy-efficient systems.

- Variable Primary Flow (VPF): VPF systems optimize the flow of chilled water based on cooling demand. By adjusting flow rates according to load requirements, VPF systems minimize energy consumption and enhance system performance.

Practical applications of chilled water systems in commercial buildings include

- Large Office Buildings: Chilled water systems efficiently cool office spaces, providing a comfortable working environment for employees.

- Hotels and Resorts: Chilled water systems are extensively used in hotels and resorts to cool guest rooms, common areas, and dining spaces.

- Hospitals: Precise temperature control is crucial in healthcare settings. Chilled water systems ensure optimal cooling for patient rooms, operating theaters, and medical equipment.

- Data Centers: Chilled water systems play a vital role in cooling data centers, maintaining the ideal operating temperatures for sensitive server equipment.

Conclusion

Chilled water systems are an integral part of efficient cooling in commercial buildings. By understanding their components, mathematical principles, and practical applications, building owners and HVAC professionals can make informed decisions regarding system design, operation, and energy efficiency. The optimal cooling provided by chilled water systems enhances occupant comfort, supports critical operations, and contributes to sustainable and cost-effective building management.

To learn more about HVAC Chilled Water Systems, kindly follow the given link: https://augmintech.com/

Hello! How far away from the chiller can the air condenser be placed? Is it possible to have a freon route for 25 meters?

Many systems can handle a distance of up to 15-30 meters (50-100 feet) without significant loss of efficiency. Beyond this distance, additional considerations may be required, such as the use of longer refrigerant lines.